Industrial automation is used in many industries such as robotics, manufacturing and automotive. This was originally revolutionised by the manufacturing industry to increase efficiency and productivity.There are also other companies where industrial automation has become beneficial such as logistics, healthcare and agriculture. Supply chain efficiency is improved in logistics thanks to industrial automation and you can improve patient outcomes by the reduction of medical errors when it comes to healthcare. In the agriculture field, crop yield can be improved as you can use precision agricultural techniques for irrigation, harvesting and planting. Industrial automation also has a positive impact on the environment as it focuses on energy efficiency.

Improved efficiency is the number one benefit of industrial automation.

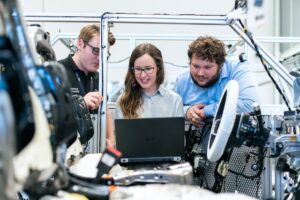

If there are time consuming tasks and repetitive activities in your business and you are wondering how to automate my factory, you can look into how to hire a control systems specialist. By automating many of the tasks in your factory, you can minimise human error and achieve a higher level of accuracy and quality. You will also be able to increase your production capacity by automating industrial processes. As your reliance on workers will reduce, you will be able to operate the factory 24/7 without any breaks in between. You don’t need to halt operation for shift changes. The system can be designed in a way that it can run consistently with minimal downtime. This will increase your production capacity and profits.

There are certain factory tasks that are very dangerous to workers. You can remove workers from dangerous environments and handling dangerous materials to reduce workplace injuries and accidents. You can use automated equipment in these areas so that dangerous tasks can be undertaken without human involvement. This will make your workplace safer and you will also save money when workers’ compensation claims are reduced. As you are incorporating more machinery into the factory, you will be reducing labour. There are many tasks where manual labour can be replaced by automation and this way, you will be dealing with lower staffing requirements and therefore reduced labour costs. The risk of employee turnover is reduced due to automation and you can improve consistency in the production process.

As human error is minimised,

You will be able to achieve higher quality in the end product. As you are well aware, automated processes are more precise and consistent compared to manual processes and you will be able to monitor these processes real-time to make improvements where necessary. You can also analyse the production processes and your control systems specialist will be able to optimise the system further to suit your needs. You will be able to enjoy increased flexibility when it comes to the manufacturing process as you can complete different tasks and produce different products by reprogramming the automated equipment. This will allow a greater degree of adaptability so you will not be falling behind when the market changes. This gives you a competitive advantage as you are able to provide products that are in demand at a faster rate at a lower cost.